- Home

- About us

- News & Events

- Corporate business

- Engineering performance

- Contact us

- National regulations

-

National service hotline400-117-5858

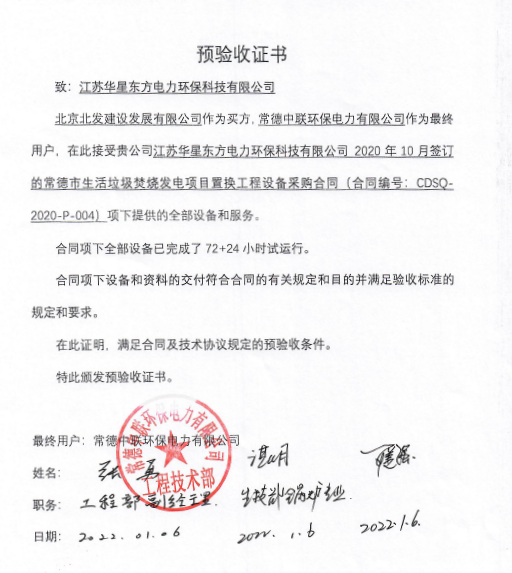

The flue gas cleaning (FGC) project undertaken by Huaxing for Phase III of Changde waste incineration power plant in Hunan Province passed 72+24 hours trial operation on January 6, 2022.

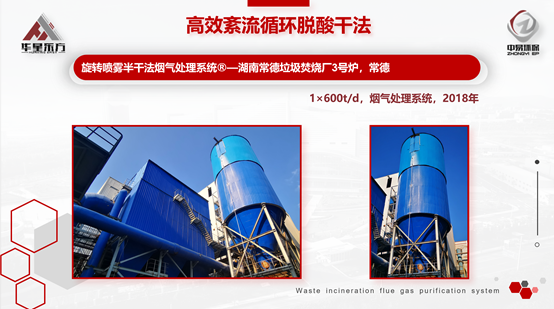

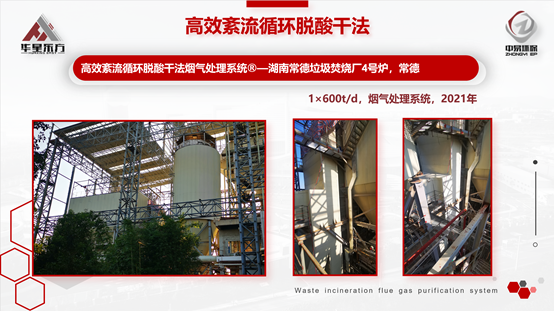

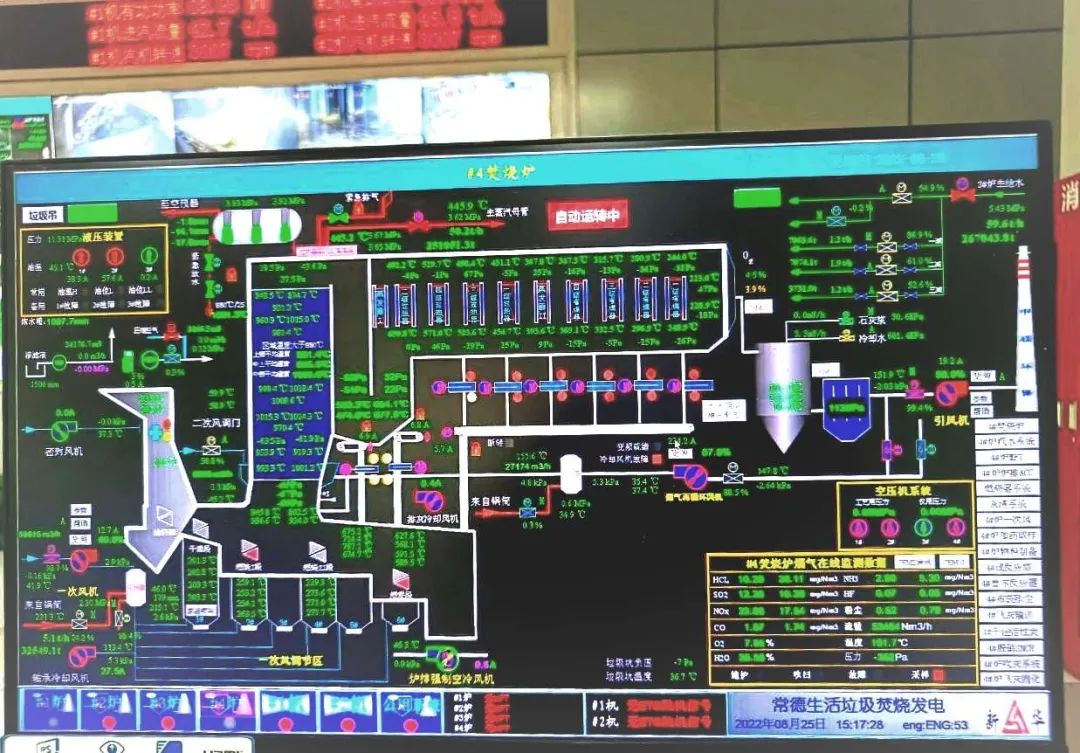

The plant is designed to incinerate 600 tons of municipal solid waste per day, equipped with a 1x600 t/d mechanical grate incinerator and a set of FGC equipment. The FGC system is mainly used to remove particles, acid substances, heavy metals, and other pollutants at the outlet of the waste heat boiler, meeting the emission requirements of the plant. The FGC system adopted the combined process of "SNCR in-furnace denitration with urea + semi dry method with Ca(OH)2 + dry method with Ca(OH)2 + activated carbon injection adsorption + dry method with high-efficiency turbulent circulation deacidification + bag filter with mass-returning + SCR reserved +fly ash conveying, storage, and stabilization+ ID fan”. The flue gas online analyzer is set at the inlet of the semi dry reaction tower and the outlet of the semi dry reaction tower . CEMS is set at the chimney inlet. The automatic control of reagent dosing is realized. It is an EP project of Huaxing.

As China's incineration equipment is gradually moving towards the international market, when participating in international exchanges and bidding activities, Huaxing experienced that the mainstream of flue gas cleaning technology was recently changing from semi-dry / wet method to efficient dry method. In particular, when Huaxing assisted the domestic enterprises to go abroad, the higher boiler efficiency obtained by European and American enterprises due to the lower boiler exhaust gas temperature has increasingly become a weak point for Chinese equipment to bid for international projects.

Since 2016, in order to understand and master the latest trend of future FGC process, the technical team of Huaxing East has successively visited some incineration plants in Europe, carried out basic contacts and communications with European counterparts, and contacted the introduction of the new dry-process.

At the end of 2017, Huaxing and its European partner jointly signed the Beijing Gao'antun Medical Waste Project for the first time, taking the lead in establishing the use of the dry-process of "Efficient Turbulent Circulation Deacidification".

In 2018, Huaxing successfully completed the industrial solid waste project in Thailand with its European partner, established the first cooperation.

Since 2019, Huaxing East & its European partner and Beifa Construction of Beijing Enterprises Group have applied this process to the Changde Phase III WTE plant. The new dry-process was implemented in 2020. The flue gas was connected in July 2021, and the 72 hours acceptance was completed in early 2022. As of the date of publication, the system has been running smoothly for 1 year and 3 months.

常德3號爐連續(xù)一年排放控制數據

1 Year's Continuous Emission Control Data

of Changde No. 3 Boiler

常德4號爐連續(xù)一年排放控制數據

1 Year's Continuous Emission Control Data

of Changde No. 4 Boiler

Compared with the traditional SDA process in Changde Phase II, its continuous cycle operation index is close, but the lime consumption is as low as 5 kg/ton MSW. The investment in the slurry preparation system and the energy consumption for operation and maintenance are saved.

The significance of the technology:

1. It solved the long-term stable and controllable operation of the material circulation under the condition of high-moisture grate furnace in China. Since the introduction of NID and Turboprop in China, except for a few grate furnace and most fluidized beds, there are rarely successful applications in China. Huaxing has participated in the SDA technical transformation of the circulating dry process in Cangzhou, Baoding, Shijiazhuang, etc. System operation was unstable in Haikou Phase I, Xiamen. The moisture content in flue gas and fly ash led to the instability of the circulation, which led to the failure of bed formation and the failure of system operation.

2. Sodium bicarbonate is introduced to reduce material consumption through material circulation. SCR is moved upstream and external economizer + two-stage activated carbon dry and bag process are installed to reduce steam consumption. It opens up a way for ultra-low emission from wet process to double-bag dry process.

3. It provides a solution for the original SDA semi-dry process to further achieve ultra-low emissions by adding a dry process under the condition of limited site.

4. By improving the control of SDA semi-dry flue gas exhaust temperature, adding sodium bicarbonate circulation combined with MHI's formula of denitration bag and its unique low-temperature regeneration, it is possible for the ultra-low emission transformation of the old incineration plant with extremely tight site.

Huaxing East is committed to exploring and practicing the best solid waste FGC solutions, and accumulating engineering application data for the industry.

The achievements of Huaxing East in Hunan Province include Changde Phase II & III, Shimen, Wugang, etc.